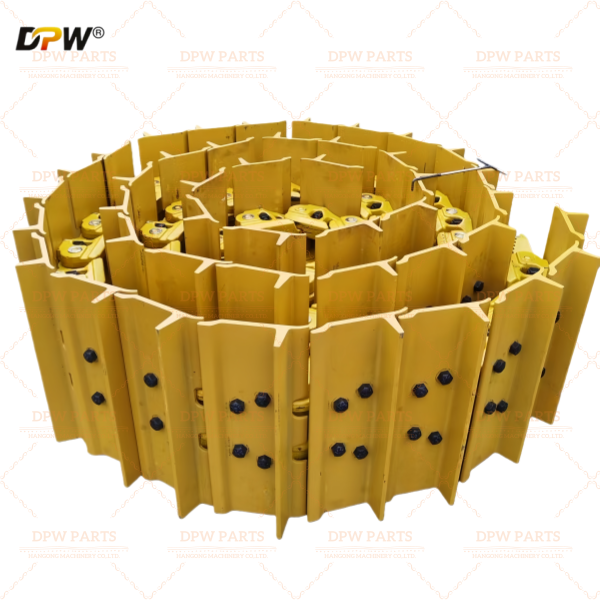

Caterpillar CA5537145 Track Group D8R 44L 610MM PPR Lubricated Type / Heavy duty Bulldozer undercarriage parts manufacturers and suppliers based in Quanzhou China-HAN GONG / DPW PARTS

Product Specifications

Introduction to PPR Lubricated Track Groups for Heavy-Duty Bulldozers

In the realm of heavy earthmoving, the track group is the literal driving force of a crawler tractor. For a machine like the Caterpillar D8R, operating in high-production, high-abrasion environments, selecting the correct track configuration is a critical operational decision. The PPR (Prolonged Service, Rebuilt) Lubricated Track Group, specified under part number CA5537145, represents a premium undercarriage solution. Designed with a 44L (44-link) count and a 610mm (24-inch) pitch, this assembly is engineered for extended service life in severe applications by combining robust construction with a sealed, lubricated pin/bushing system to minimize internal wear. Manufacturers based in industrial hubs like Quanzhou, China, such as HAN GONG (branded as DPW PARTS), have developed specialized expertise in producing these complex, performance-critical assemblies.

Technical Specifications & Engineering Analysis: CAT CA5537145 Track Group

This assembly is a complete, ready-to-install track belt built to Caterpillar D8R specifications for demanding use.

Core Configuration & Design Philosophy:

PPR (Prolonged Service) Design: This signifies components built to enhanced durability standards, typically featuring increased material thickness in high-wear areas, upgraded seal profiles, and superior heat treatment. It is the specification of choice for mining, quarrying, and heavy rock excavation.

Lubricated Track Chain: The defining feature versus "dry" or "sealed" chains. Each pin and bushing joint is a sealed cavity, pre-filled with a special high-temperature, extreme-pressure (EP) grease. This internal lubrication dramatically reduces friction and wear between the pin and bushing, significantly slowing chain pitch elongation—the primary cause of track chain failure.

44L / 610mm Pitch: The 44-link count is engineered for the D8R's track frame geometry, providing optimal ground contact and tension distribution. The 610mm pitch indicates the distance between consecutive pin centers, a critical dimension that must perfectly match the sprocket tooth pitch for smooth engagement.

Component-Level Material and Manufacturing Science:

Track Links (Sidebars): Manufactured from high-carbon, boron, or alloy steel forgings (e.g., 40Mn2, 50Mn). The forging process ensures superior grain flow and fatigue resistance at the high-stress pin and bushing bores. PPR links may feature induction-hardened bore surfaces to resist wear and deformation.

Track Bushings: The primary wear component. Made from through-hardened alloy steel (e.g., SAE 8620), carburized and hardened to a core-controlled depth, achieving a surface hardness of 55-62 HRC. Precision grinding ensures perfect roundness and concentricity for even wear against sprocket teeth.

Track Pins: Fabricated from case-hardened, low-alloy steel. They undergo deep-case induction hardening to achieve an extremely hard exterior (58-63 HRC) while maintaining a tough, ductile core to withstand shear and bending stresses.

Advanced Sealing System: The heart of a reliable lubricated chain. Utilizes a multi-stage sealing cartridge, often of the "D6R/D7R style" or "Delta Seal" design, comprising:

Precision-ground alloy steel seal rings forming a primary metal-to-metal barrier.

Hydrogenated Nitrile (HNBR) O-rings for elasticity and high-temperature resistance.

Dust lips and retainers to lock the assembly in place and exclude external contaminants.

Track Shoes (Grousers): Typically high-tensile manganese steel castings or forged alloy steel, securely attached to each link assembly via heat-treated bolts. Shoes are available in various profiles (e.g., single-grouser rock, multi-grouser standard) to match ground conditions.

The Quanzhou Industrial Context & HAN GONG / DPW PARTS Manufacturing Profile

Quanzhou, within Fujian Province, is a significant industrial center in China with a developed ecosystem for machinery parts manufacturing, including foundries, forges, and precision machining facilities. HAN GONG, operating as DPW PARTS, leverages this integrated supply chain to specialize in undercarriage systems.

Manufacturing Capabilities and Quality Assurance:

Integrated Production Line: Controls the process from raw material (verified alloy steel) through forging, machining, heat treatment, seal assembly, and final track group assembly.

Precision Forging & CNC Machining: Employs closed-die forging for track links and uses multi-axis CNC machines for precise machining of pin/bushing bores, seal grooves, and chamfers—all critical for seal life and proper articulation.

Controlled Heat Treatment: Utilizes computer-controlled atmosphere carburizing furnaces and induction hardening lines to achieve the exact case depth, surface hardness, and core toughness required for PPR-level components.

Clean-Room Seal Assembly: The lubricated chain assembly is conducted in a controlled environment to prevent particulate contamination during the installation of seals and injection of specialty grease.

Comprehensive Testing Protocol:

Spectrochemical analysis of raw materials.

Hardness testing (Rockwell, Brinell) on pins, bushings, and link bores.

Dimensional inspection via CMM for critical pitch and bore measurements.

Seal cavity pressure testing to verify integrity before shipment.

Value Proposition for Global Equipment Operators

Sourcing the Caterpillar CA5537145 D8R 44L PPR Track Group from a manufacturer like HAN GONG / DPW PARTS offers:

Direct OEM Compatibility: Designed to meet or exceed the original Caterpillar dimensional, material, and performance specifications for a true plug-and-play replacement.

Focus on Severe Service: The PPR lubricated design is specifically targeted at applications where maximizing undercarriage life is paramount to controlling operating costs.

Total Solution Supply: Capability to provide not only the complete track group but also individual sub-components (links, pins, bushings, seals) and matching undercarriage parts (rollers, idlers, sprockets) for streamlined procurement.

Cost Efficiency without Compromise: Provides a viable, high-quality alternative that reduces capital outlay for major undercarriage rebuilds while maintaining machine productivity and reliability.

Application and Sourcing Guidance

Accurate Verification: Before ordering, confirm the exact machine model (D8R), serial number range, and existing track configuration (pitch, link count, lubricated type) to ensure CA5537145 is the correct assembly.

System-Wear Assessment: Installing a new PPR track group on a severely worn undercarriage (sprockets, rollers, idlers) will accelerate wear on the new chain. A system-wide assessment is recommended.

Professional Installation: Proper installation following OEM guidelines for track tension (sag measurement) and shoe bolt torque is critical to realize the full service life of the assembly.

Supplier Qualification: Engage with suppliers who provide transparent material certifications, detailed manufacturing process descriptions, and clear warranty terms.

Conclusion

The Caterpillar D8R 44L PPR Lubricated Track Group (CA5537145) is a precision-engineered system built for endurance in the most punishing environments. Manufacturers based in Quanzhou, China, such as HAN GONG / DPW PARTS, have established themselves as credible sources for these complex assemblies by investing in vertical manufacturing integration, material science, and rigorous quality control. For fleet managers and heavy equipment operators worldwide, partnering with such a specialized manufacturer provides access to durable, OEM-compatible undercarriage solutions that directly support operational uptime and optimize the total cost of ownership for critical assets like the Caterpillar D8R.